Darkroom photo paper comes in two forms: Resin-Coated (RC) and Fiber-Based (Fiber or FB). There are pro's and con's of both for normal darkroom printing that have been covered in-depth by dozens or hundreds of different photographers. Lumen printing, however, is not traditional darkroom usage. There are some different reasons you may want to work with either RC or FB papers for your lumens.

First off, remember that lumen color profiles vary by the type of paper and, yes, that includes a difference like RC vs FB. Not always significantly different, but different. Some brands might vary to a considerable degree, but all of them will vary at least a bit. So one thing you have to consider when making your choice is simply if you care. Maybe the specific colors you want don't come from RC, or can't be produced on Fiber. In that case, this guide will just help you deal with the downsides of that particular material.

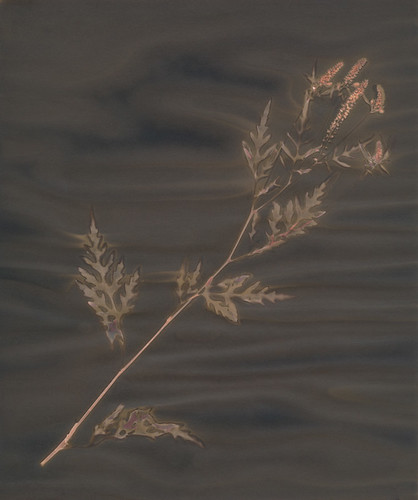

|

| The result of RC paper stuck to glass |

The first big pro of RC paper is that it's cheaper than Fiber, normally by a significant amount. That's a huge consideration for a lot of folks, especially if lumen printing is just a hobby or something you want to try out before investing.

Next, RC paper dries a lot faster than fiber paper and it doesn't wrinkle. It doesn't warp, bend or ripple like fiber paper does. It dries smooth and flat, which is wonderful!

My biggest complaint against RC paper is that it tends to have a fairly glossy surface, even the lusters, so it can be very hard to keep clean. Fingerprints show up easily, especially if your fingers are damp when you handle the paper, and dust is a huge issue. So huge that it takes a considerable amount of time (though that can be shortened with a few tricks) to clean up any scans of RC prints. Just dust. Eveywhere.

I have noticed that RC paper tends to be "stickier" and sometimes glues itself to the glass of whatever frame I'm using, especially if the leaves sweat a great deal or the paper was moistened during exposure. This can be overcome by allowing glued sections of the print to soak in water so they simply lift off, but that comes with the risk of water exposure changing the tone of the print or introducing unwanted elements. That can still be preferred to a print with large white areas where the gelatin emulsion has been completely torn away because it became attached to the glass of the frame.

Fiber-Based (FB) Paper

|

| Fiber paper so warped that the ripples left shadows on the print itself. |

In lumens, the primary darkroom benefits of fiber paper (improved archival lifespan and better reaction to chemical bleaching or toning) are less apparent because lumens generally aren't archival and they don't normally get toned or bleached. However, some people still consider the archival lifespan of the print important and may prefer fiber for that reason.

My only reason to prefer fiber is that it is far more absorbent than RC (as in, it's absorbent at all) which is very useful in some situations. There are two specific situations that I run into quite often, so I'll detail them, but any time you need something to soak into your paper, Fiber is where it's at.

If you want a tonal range that can only be produced with a wet paper, you can soak fiber paper and it'll stay moist for quite a while, thus providing the 'wet' color profile. Since it wicks moisture, you can also put it on some soaked towels or something and it'll stay moist longer. This can be useful!

Similarly, you can alter a lumen print's appearance by adjusting the pH of the paper, adding salt or other metals to the paper and you can even layer other processes (like cyanotype or salt print) onto lumens. All of these are much easier done with fiber paper as a result of its absorbent nature.

The downsides of FB paper has are simple and yet annoying: it is very difficult to keep flat and it takes a long time to wash or dry. I hate having to take an iron to my fiber prints for 20 or 30 minutes to flatten them, only to have to continue pressing them under heavy books for days or weeks to ensure they actually stay flat. It sucks. There are no true workarounds to these issues.

Of particular irony, the addition of liquids (a primary function for FB papers) to the printing process aggravated the flaws of long drying time and warped surfaces. The easiest fiber prints to deal with are the driest ones, but dry prints tend to be fairly boring and aren't taking advantages of the absorbent nature of fiber paper.

No comments:

Post a Comment